General informations

- EN 61558-2-1 Low capacity power insulation transformers

- EN 60076 Power transformers or autotransformers (< 1 000 VA single phase ; < 5 000 VA three phase)

- EN 61558-2-2 Control transformers

- EN 61558-2-4 Isolating transformers

- EN 61558-2-6 Safety isolating transformers

- EN 61558-2-13 Low capacity power autotransformers

- EN 61558-2-15 Isolating transformers for medical usages

- EN 61558-2-20 Inductors

- EN 60947-4-1 Start-up autotransformers three phase motor

- UL5085-1 & CSA 22.2 Transformers for USA and Canada

Indicated levels are for power in VA or kVA, it is the product of the secondary rated voltage by the nominal intensity for single phase devices, and √3 for three phase as devices.

- B Maximum temperature 130°C

- F Maximum temperature 155°C

- H Maximum temperature 180°C

Depending upon their power or their characteristics, magnetic circuits are made :

- Silicon electrical steel (1,7 W)

- Grain oriented silicon steel (0,6 W)

All our equipment is systematicaly impregnated with an H class varnish, either the complete transformer :

- To avoid moisture absorption ,

- To stop wear due to vibration,

- To improve thermal exchange,

- To reduce noise level.

On request, we also apply a special treatment for extreme environments. On top of a complete treatment by impregnation, we add one overall coat of “anti flash” varnish. The last coat improves resistance to moisture, mushrooms and all conductive dusts.

- Classe 0

- Classe I (with earthing terminal)

- Classe II (on request)

- IP21 – IK08 (except the bottom)

- IP54 – IK08

- Other on request

- Supplementary insulation : in this case, it acts like a barrier for a primary insulation fault and carries the fault to earth without affectif the secondary side.

- Reduction of static noise : if used as a computer supply, it carries part of the network static noise to earth.

- An autotransformer has only one winding rated for the highest voltage. The lowest voltage is obtained on the middle tap changer.

- Therefore, there is no insulation between circuits and use of this type of transformer must not be used as a safety transformer or to achieve circuit separation. However, the transformer is a very economical solution to obtain a voltage change. (Ex: a 10 000VA autotransformer will be the same size and losses as a 4 000VA transformer).

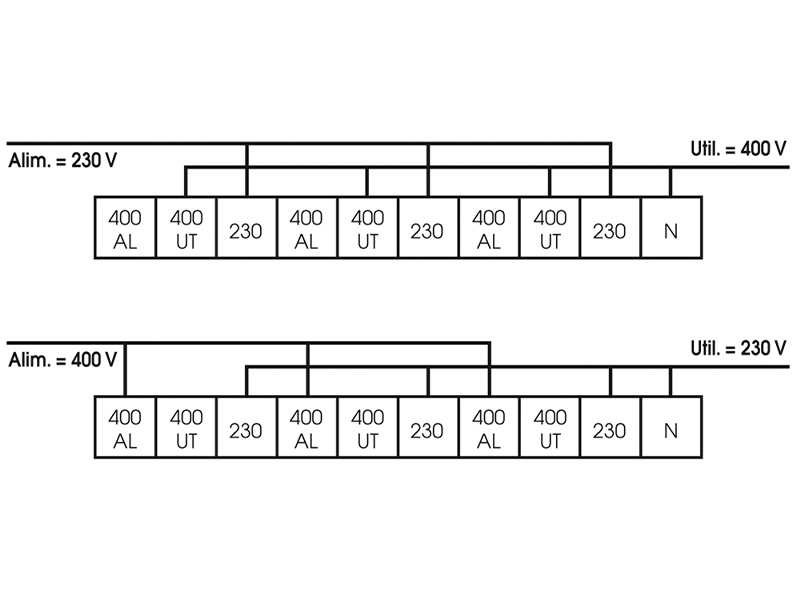

- Our AMS and ATS autotransformers are equiped with a compensation tab to insure a real reversibility in use.

- The sizing of an artificial neutral is directly connected to the network voltage and to the necessary intensity in the neutral. The winding is crossed only by this intensity. The power absorbed on the network does not intervene.

- The divisor of tension is used to create a neutral on a three-phase network. It does not change the value of the network voltage.

WARNING, with the divisor, we do not realize change of regime of the neutral, for it is necessarily needed a transformer.

- All our equipment and winding characteristics are systematically tested. On request, we can provide a test report to the customer.

- All the materials used and the process to be operated are reported on a manufacturing file which follows the product throughout its realization. This file is infinitely preserved in paper and computer versions. The electrical specifications recorded can be the object of a trial report to be asked with order.

Français

Français